A new fleet manager and a subsequent strengthening of relationships with core suppliers have resulted in significant cost reductions, compliance improvements and operational efficiencies at Turnpower Services over the past three years.

The achievements are even more impressive when considering that, over the same period, the property and facilities management company’s fleet has trebled in size, now sitting at 130 vans (from Kangoos to Lutons) and 20 company cars.

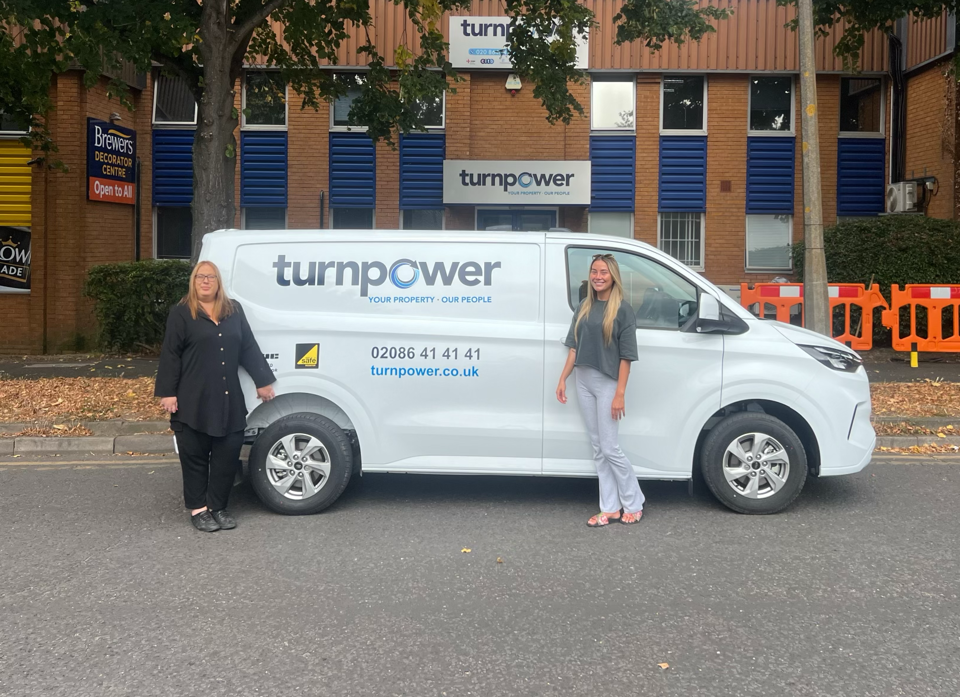

Maria Smith (pictured above left) was appointed Turnpower fleet manager in 2021, just as its business – and fleet - started to burgeon. With a motor trade background working in bodyshops, breakdown, accident management and motor insurance claims, she brought a wealth of skills and a crucial understanding about the important role that suppliers can play in supporting fleet activities.

Turnpower was between fleet managers when Smith was recruited and had relied for several years on various managers each handling different bits. However, Turnpower managing director Paul Gomez recognised the need for dedicated fleet resource as the company began to expand nationwide from its London heartland.

It wasn’t long before Smith was putting forward the case for a fleet assistant to support her by taking on some of the time-consuming day-to-day jobs. Grace Gomez (pictured above right), daughter of Paul, joined the family business just over a year ago, initially to focus on administrative duties, freeing up Maria to look at the wider fleet policy.

Keepings vans on the road

One of the first areas to come under the microscope was fleet funding. Historically, Turnover bought its own vehicles, but over the past couple of years has been migrating to long-term rental with Herd Group. The current split is 60% Herd, 40% Turnpower but more vans will move to the lease agreement as they are replaced.

“We found it more cost effective to use Herd because the vehicles are fully maintained with breakdown support over the three-year operating cycle,” Smith said.

In addition to budgetary controls, the main benefit is vehicle uptime, which is one of Smith’s biggest priorities. A single van off the road for a day could affect five major jobs with costs running into thousands of pounds.

“Our main objective is to keep drivers off the road for as little time as possible,” she said. “We are 365 days a year and 24/7 and our work is very reactive and needs to be done immediately so we have to make sure our engineers are on call and ready to go.

“It’s not just a monetary cost,” Smith added. “It’s also about meeting our SLAs and making sure our customers’ needs are met as we deal with a lot of blue chip companies.”

The three-year replacement cycle helps to minimise downtime – Turnpower defleets before the first MOT is due - by ensuring the fleet is full of newer, more reliable vans.

Herd prioritises Turnpower’s vans, booking them in for repair at short notice and offering replacements. Often, though, the company turns to its own pool fleet of five vans which are in constant use. Fully liveried and equipped to Turnpower’s requirements, this pool fleet is a more efficient and effective option.

A mobile van servicing network supports the uptime management programme, visiting engineer’s houses to carry out early morning servicing to minimise disruption during the day.

“It can be done in just a couple of hours and keeps everyone moving,” Smith said.

Underlining her recognition of the benefits of strong supplier relationships, Smith uses a network of smaller, local repair businesses supported by the account team at Herd which authorises and stays on top of the work to ensure it is completed as quickly as possible.

“We've got a good relationship with Herd. We have regular meetings and open conversations about everything,” Smith said.

“Herd Connect makes SMR quicker and more cost effective. We have unlimited access to their team of experts who can help us manage every aspect of our fleet and help deliver long-term savings.”

The new approach is working: the average number of days vans are off road has fallen.

AI-enabled dashcams

All vans are now fitted with telematics plus forward and driver facing cameras. The latter, which Smith describes as “game changing”, help to speed up insurance claims by revealing fault.

They are also AI-enabled, so if the driver is holding an object that looks like a phone, it will notify the fleet team.

Initially there was some push back from drivers, but most now recognise the benefits to them, according to Gomez.

She said: “It does work for everyone because in the event of an incident, even the guys that don't like the cameras, they're glad that there was footage of it, especially if it wasn't their fault.”

Gomez is responsible for running all the driver behaviour reports from the Samsara telematics system to assess driver efficiency and safety, including speeding and harsh braking.

“We can see who the best and worst drivers are, and we can give them additional training but also reward the best ones,” she said.

Driver of the month points are accrued from the telematics data and dashcam evidence as well as incidents and customer/public complaints with the winner receiving a voucher. The scheme was introduced a year ago when Gomez started.

“We are trying to get them to have a bit of initiative to drive better by giving them a reward; we don't want to make it all about the bad stuff,” she said.

“They all do a driving assessment before they start with the company so we can see roughly what they'll be like once they actually start.”

Gomez added: “A lot of the guys always ask every month ‘have I gone down the list?’ so they are listening, and they want to get better.”

Smith would like to bring in driver appraisals as part of the annual employee appraisal to provide feedback, tips and pointers about improving their performance behind the wheel.

“We think it's equally important,” she said.

Over the past couple of years, at-fault claims have reduced by 50%, helping to reduce insurance premiums. No surprise that Smith and Gomez have regular meetings with their insurance partner to discuss new ideas.

Training is primarily eLearning but on-the-road coaching is likely to be introduced as a result of feedback from the insurer.

“All the time we are trying to evolve by speaking to different people, to get new ideas,” said Gomez.

“Me and Maria were also thinking about doing some training that teaches us how we can take the guys out as part of their induction when they start the company.”

Also on the agenda is mental health and how that can affect an employee’s driving.

Electrification challenges

With drivers on call every four weeks, and a mix of day and night-time shifts, Turnpower has a return-to-home van fleet which throws up additional challenges when considering the electrification journey.

Many drivers are unable to have home chargers, which will mean reliance on the public charging network. Turnpower has started trialling some full electric vans which highlighted the issue with availability of local chargers.

Smith said: “Even though the engineer had the charging points in his road, other people were parking there, so he couldn't charge his van.”

Progress has been much swifter with the company car fleet, which is now almost entirely full electric.

“We've worked with our fuel card company, and they've helped us fix chargers on employees’ houses, so they intercept their electric bill and send the invoices to us for charging their cars,” said Smith.

“We've rolled this out in the last six months to see how they get on with charging them at home. Going forward, it’s probably something we do with the vans where we can.”

Drivers also have charge cards so they can use the public network.

“Moving forward, we're hoping that there will be more electric points and that's something that we can start implementing, but right now, probably not,” Smith added.

She has regular update meetings with MD Paul Gomez to keep him informed about fleet initiatives. It has help raise fleet up the agenda.

One issue she has sought to address recently is van security. A large proportion of Turnpower’s business is in London, a hotspot for break-ins and attempted theft.

“We fit deadlocks, we have plates, we do the anti-peel as well. So we try and be as secure as possible,” she said.

“That's also why we keep our own pool of vans, because we have all that security on them as well.”

The company saw a rise in attempted thefts last year but since the new measures have been implemented, the numbers have dropped significantly, while any attempts remain unsuccessful attempts.

Summing up her approach to the Turnpower fleet, Smith said: “We literally look at everything we do because we're such a huge outgoing for the company.”

Login to comment

Comments

No comments have been made yet.