The latest electric vehicle battery recycling techniques could reduce reliance on importing minerals to create new ones in Europe by up to 25%.

Cracking the code on recycling EV batteries is a key component to addressing net zero challenges.

It addresses the key criticism from EV sceptics that production of zero emissions technology is a zero sum game due to the damage done to the enviornment to create and dispose of them.

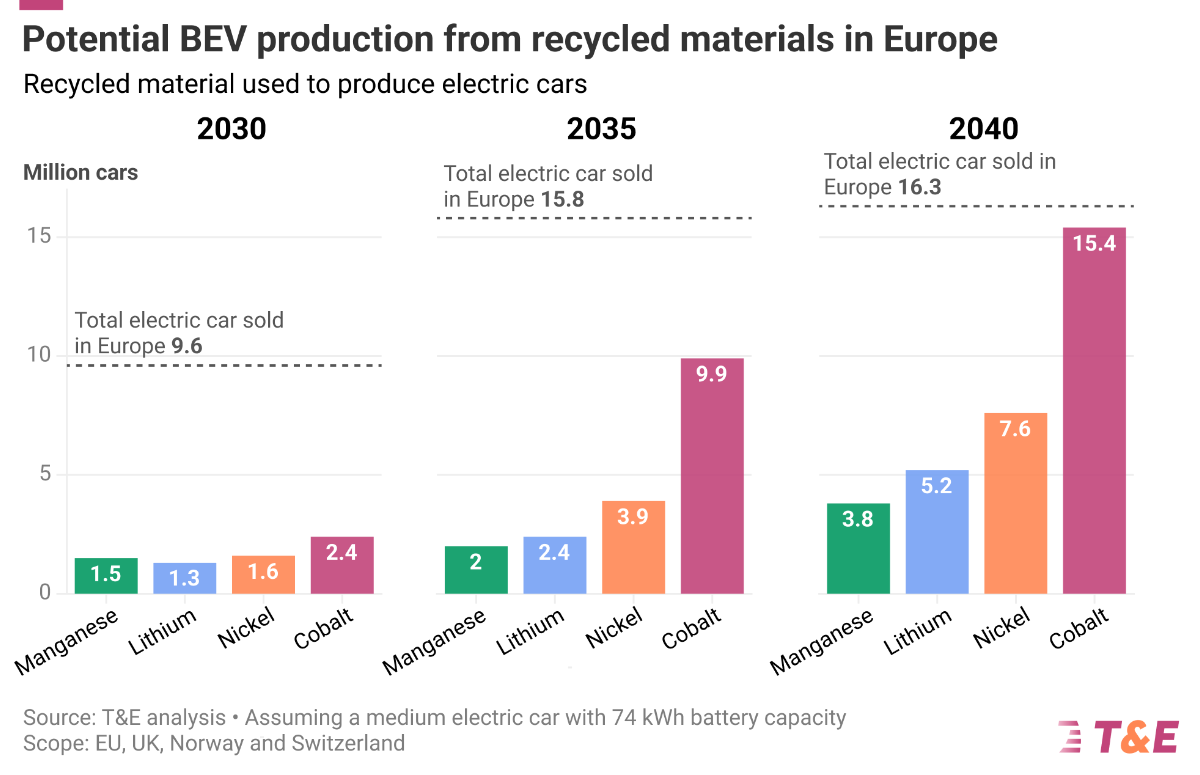

Materials from end-of-life batteries and gigafactory scrap have the potential to build up to 2.4 million EVs locally in 2030, according to research by Transport & Environment (T&E).

However, the EU and the UK will not be able to harness this potential unless they secure recycling projects that are at risk of being cancelled, T&E said.

Recycling spent cells and production scrap could provide 14% of the lithium, 16% of the nickel, 17% of the manganese, and a quarter (25%) of the cobalt that Europe will need for electric cars in 2030, the study finds.

These could then rise dramatically, and the region has the potential to be almost self-sufficient in cobalt for electric cars in 2040.

Julia Poliscanova, senior director for vehicles and emobility supply chains at T&E, said: “If Europe delivers on its recycling plans, it can slash its reliance on imported critical metals.

“The expected volumes of locally recovered materials can enable Europe to build millions of clean electric vehicles locally.”

Recovering battery materials will also replace the need for primary ores.

The research finds recycling EV minerals in Europe could avoid the need to build 12 new mines globally by 2040: four lithium, three nickel, four cobalt, and one manganese.

This would also reduce the potential negative impacts on water, soil and biodiversity from those mines.

As well as reducing both extraction and imports of raw materials, recycling in Europe could cut the carbon footprint of sourcing lithium by almost a fifth (19%) compared to extracting it in Australia and refining it in China.

This is due to Europe’s cleaner electricity grid.

Almost half of the planned recycling capacity is at risk

But to reap the economic and sustainability benefits, Europe needs to scale up its recycling industry.

Almost half of the recycling capacity that has been announced for the region is on hold or uncertain to go ahead, according to the report.

T&E called on the EU and the UK to urgently prioritise support for recycling across their policies and funding programmes.

It said the EU’s upcoming proposal for a Circular Economy Act should support the scaling of local recycling factories while also restricting exports of battery waste and simplifying the shipment of end-of-life battery materials within Europe.

Poliscanova added: “Neither the EU nor the UK are ready to capture the recycling opportunity.

“Almost half of the planned recycling capacity is at risk due to high energy costs, a shortage of technical expertise or a lack of financial support.

“It’s time to start treating battery recycling like another clean tech and prioritise it in our policy and grant making.”

Login to comment

Comments

No comments have been made yet.