The Health and Safety Executive (HSE) has issued a safety alert for those carrying out work on vehicles with air suspension systems.

The warning is particularly being aimed at those working in vehicle repair workshops, the roadside repair and recovery industry and customer sites where this work is undertaken.

Vehicles are commonly fitted with air suspension, including buses and coaches, refuse vehicles, goods vehicles and tankers.

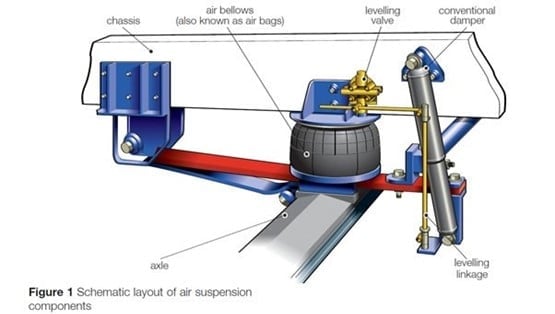

On a vehicle with an air suspension system, inflated rubber bellows (also known as airbags) are supplied with air from the vehicle’s air compressor via a storage system.

These take the place of conventional springs at each wheel or axle and automatically ensure a consistent ride height, regardless of the load being carried.

A typical set up is shown below

While these are produced by numerous manufacturers, HSE says that the hazards are common including:

- Clearance suddenly and unexpectedly changing due to a drop in air pressure, automatic movements or air bellows rupturing or deflating. This presents a crushing hazard to those working in a position where they may become trapped eg underneath the vehicle or between the wheel and chassis.

- Work on pressurised systems resulting in violent ejection of parts under pressure and failure of components which may become projectiles.

HSE has investigated several serious incidents, including fatalities, involving air suspension systems on vehicles that have failed. Causes of the incidents have included:

- Work being carried out on vehicles supported by the air suspension system and the airbags have catastrophically failed.

- Work has been carried out on the suspension control system or vehicle sensors and unexpected suspension movement has occurred.

- Work has been carried out without de-pressurising the air suspension system and the pneumatic air bag or associated components have ejected or ruptured.

HSE says that those carrying out or responsible for work on vehicles fitted with air suspension systems should:

- Ensure tasks are adequately planned. This includes, confirming the configuration of the particular suspension system, assessing the risks associated with each task, explaining each task so it is fully understood by the technician, providing the necessary equipment to undertake the job safely and developing safe systems of work. These should take into account the specific tasks and control measures required.

- Undertake minimal repair work at the roadside or third-party premises. The best place to undertake such work is at an adequately equipped vehicle repair facility.

When working on vehicles with air suspension systems, it says:

- Prevent movement of suspension, either by fully deflating the system or by using suitably rated props or stands to prevent the chassis lowering. Under no circumstances should air suspension be relied upon to maintain a vehicle’s ride height or position whilst people gain access to areas where they may become trapped.

- If you are working near a lifting axle it should be isolated as it can move without notice.

- Carry out a visual check of the configuration and condition of the air suspension system.

When working on the air suspension system itself, it says:

- Undertake the actions above for working on vehicles with air suspension systems.

- Exhaust the air from the air suspension system before working on it.

- Isolate the system by physical disconnection of the air supply. The practice of temporary isolation by clamping of air suspension pipework (such as by mole grips) does not provide a secure isolation. In addition determine whether dissipation of stored air in the suspension system is required.

- For leak testing, visually inspect the empty system, then inflate and raise to full travel, leave a short period of time before inspecting for leaks. Should damage be identified, exhaust the air from the system before carrying out repairs.

Login to comment

Comments

No comments have been made yet.