An increasing demand for battery raw materials and imbalanced regional supply are challenging battery and automotive producers’ efforts to reduce Scope 3 emissions, according to McKinsey.

The company’s latest report highlights a looming supply-demand imbalance for critical battery raw materials by 2030 as the global push towards net-zero intensifies.

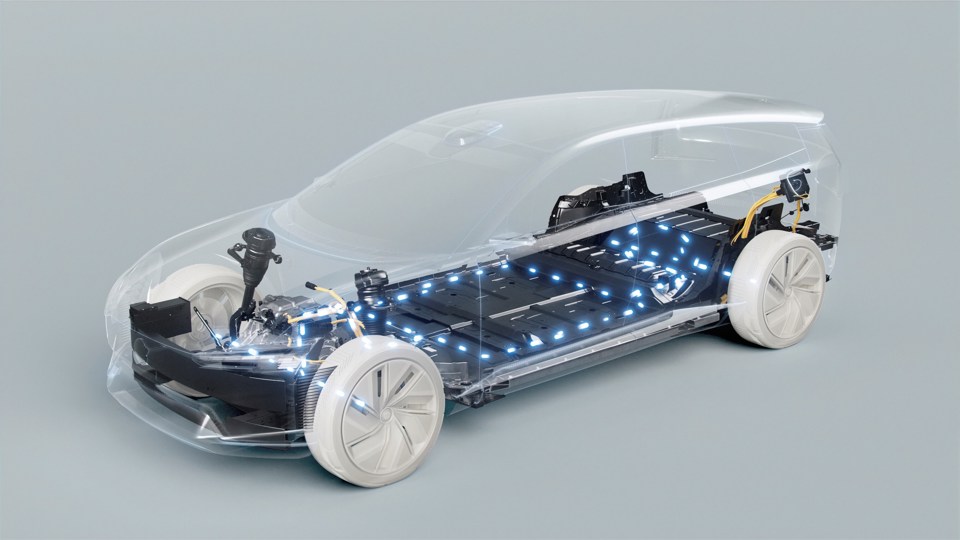

The report projects a sixfold increase in worldwide demand for battery electric vehicles (BEVs) through 2030, with annual unit sales rising to approximately 28 million from 4.5 million. This surge in demand will, according to McKinsey, significantly strain the supply of essential materials like lithium, high-purity manganese, and graphite, and put pressure on emissions reduction strategies.

Technological advancements in battery production, including the shift toward lithium iron phosphate (LFP) batteries, have proved crucial in addressing some of these challenges, the report states.

While LFP batteries reduce dependence on scarcer materials like cobalt and nickel, they still require significant amounts of lithium, manganese, and graphite. McKinsey’s analysis indicates that on average, 40% of battery emissions stem from upstream raw material mining and refining processes, making it essential to reduce the carbon footprint of these processes to protect decarbonisation efforts.

Raphael Rettig, partner at McKinsey, said: “Given the supply/demand imbalance, building the battery raw material value chain remains a challenge in many markets.

“Despite this, there are real opportunities for battery producers to lead on emissions reductions. Sourcing materials from supplies committed to low-emission fuels and power sources could cut emissions by as much as 80% in mining and refining phases. This needs to be paired with a strong focus on cost reduction given the current profitability pressure in the battery industry.”

As the industry makes strides in reducing emissions from high-impact materials like lithium, nickel, and aluminium, McKinsey analysis indicates that the relative emissions intensity of smaller materials, such as high-purity manganese, could increase. Currently, high-purity manganese accounts for around 4% of the emissions profile in an LI-NMC battery, but as LFP batteries grow more popular and larger sources are decarbonised, manganese’s share could nearly double unless specific abatement strategies are implemented.

Login to comment

Comments

No comments have been made yet.