The cost differences between repairing an electric vehicle (EV) versus an internal combustion engine (ICE) equivalent have been highlighted in a new report.

The research, published by Thatcham Research and funded by the Government’s innovation agency, Innovate UK, highlights the technical and practical differences between battery electric vehicle (BEVs) and internal combustion engine (ICE) vehicle insurance claims processes.

Despite newer BEVs featuring high fitment levels of ADAS (Advanced Driver Assistance Systems) and passive safety technologies, they are not risk or incident free.

Due to the nascent nature of the industry, BEV incident claims are currently 25.5% more expensive than their ICE equivalents and can take 14% longer to repair, suggests Thatcham.

Road collisions involving a BEV can be catastrophic for the vehicle as understanding and competence in rectifying the damage continues to develop, it says.

Battery assessment and repairability

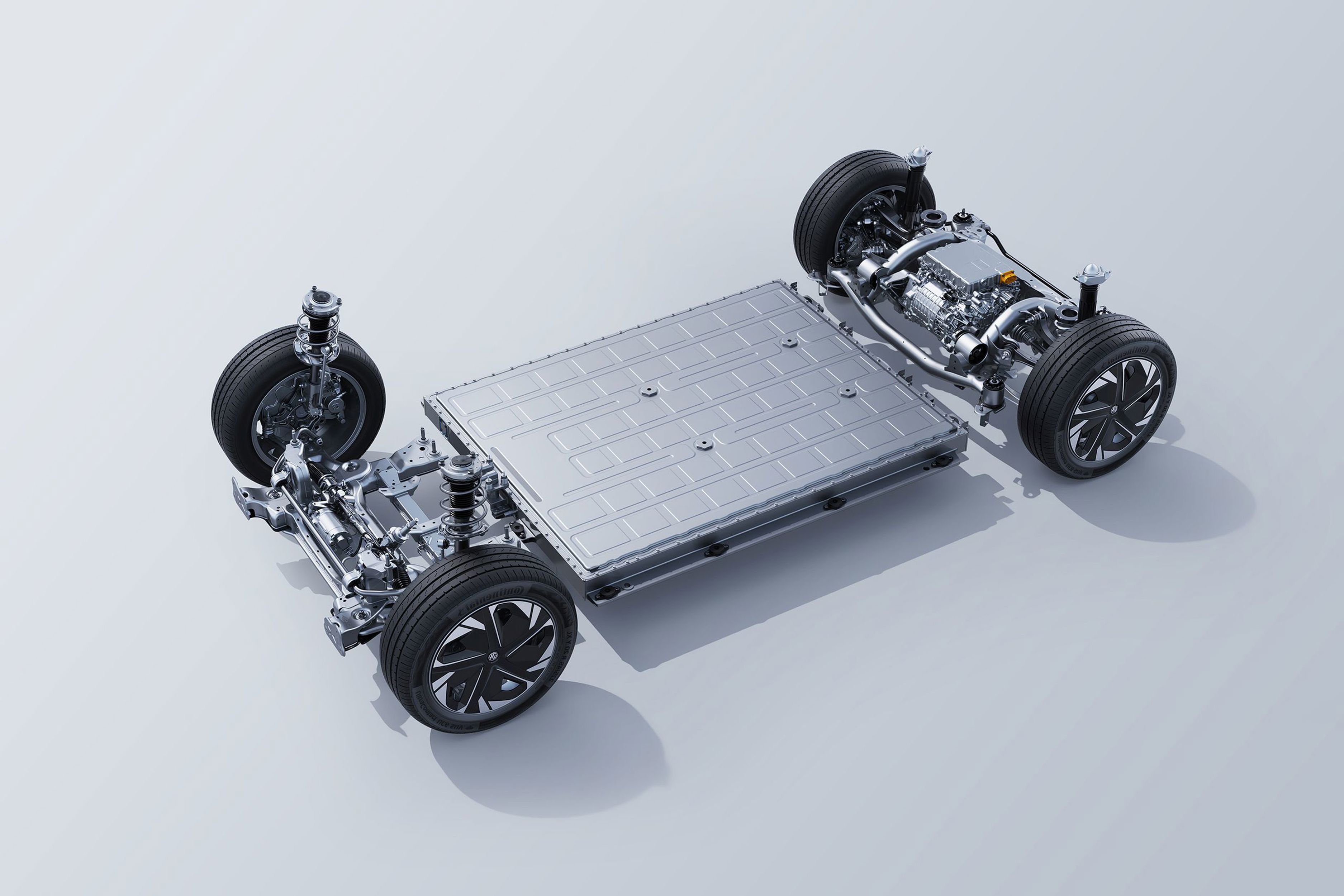

The most significant challenges identified by the report originate from the high voltage (HV) battery. BEV batteries represent a substantial percentage of the original vehicle value and are therefore rapidly presenting negative impact to the economic model of vehicle repair, says the report.

Although there is a relatively small number of BEVs in the market, there is an understandable but concerning lack of affordable or available repair solutions and post-accident diagnostics, it adds.

Thatcham Research’s data-driven modelling shows that in 2022, 9,400 vehicles were potentially involved in collisions resulting in battery inclusion in the repair. This is estimated to reach up to 260,000 vehicles annually by 2035.

Adrian Watson, head of engineering research, Thatcham Research, said: “Without meaningful change, there is a strong likelihood that claims costs will continue to rise disproportionally.

“Much of the motor insurance industry is yet to adapt to mass BEV adoption challenges, and the implications remain unquantified on repair capacity, training and skills, cost, and the lifetime sustainability of BEVs.

“This lack of awareness means many BEVs are often deemed irreparable, leading to premature write-offs because of high battery cost and the lack of value the UK ecosystem can recover from them.”

Currently, the cost of a replacement HV battery is causing a significant increase in the risk of ‘total loss’ or write-offs.

The cost of HV batteries varies widely from high-end vehicles, currently costing £29,500, to the low-end costing £14,200.

The ‘depreciation curve’ of battery cost versus average used value, says Thatcham, shows that the cost of a replacement battery is more than the used price of the vehicle after only one year.

Watson explained: “These cost increases present a significant risk to BEV uptake, reducing potential economic and sustainability gains.

“Technical solutions do exist for most if not all of these challenges. However, it is vital that credible cross-industry plans are urgently put into place that focus on addressing battery cost, diagnostics, and the creation of a sustainable ecosystem for battery repair.”

Other considerations for BEV repairability

Government guidelines state that due to fire risk, damaged BEVs awaiting repair should be stored in an outside quarantine area, at a safe distance of 15 metres from other nearby objects.

As such, an outside storage space with capacity for 100 ICE vehicles, would allow for the safe quarantine of just two BEVs, representing a potential 98% reduction in repair capacity.

The cost incurred through following recommended quarantine protocols of 48hrs will add a minimum of £60 to every claim, the report states.

If the vehicle cannot be safely stored at the repair centre there will be further costs associated with transportation to and from an alternative location, storage at the alternative location, along with a longer duration of hire vehicle.

Watson said: “This could result in a measurable rise in associated claim cost and duration, negatively impacting on the BEV ownership experience.

“This presumed rise in cost is a result of just one element of the BEV claims process flow. However, there are many other factors which may also result in further insurance premium costs due to the differing processes that follow a BEV collision.

“These range from limited access to battery diagnostics to enable a better understanding of battery health and potential repair options, to the increased weight of a BEV creating challenges to roadside recovery and a requirement for bodyshops to make costly investments in specialised repair skills and equipment.”

Recommendations

“It’s important to reiterate that most, if not all, of the outcomes highlighted by the report could be avoided with the right solutions in place,” said Watson.

The report’s authors would suggest investment in further cross-industry work to identify more detailed solutions and to make direct recommendations about a range of interventions or support to accelerate those solutions.

For example, by understanding the needs of vehicle manufacturers, repairers, insurers, and salvagers to optimise the supply of new/refurbished/recovered batteries in vehicle repair.

Chris Payne, head of networks and engineering at LV= General Insurance, which supported the research with motor insurance claims modelling, said: “We’re working hard to find solutions to some of the current challenges around EVs. This includes upskilling the next generation of technicians and redesigning and developing our new and existing repair sites.

“As an industry we also need to ensure there is collaboration between insurers, car manufactures, salvage agents, repairers and the entire supply chain.

“This will ultimately help us work towards a combined goal that enables the latest vehicle technology to be repaired safely, and efficiently with the right skills, tooling and equipment to ensure we meet the needs of the future.”

Thatcham says it will continue to work closely with Government and vehicle manufacturers to identify solutions to the issues raised by the report.

To access a copy of the report, click here.

> Interested in comparing electric vehicle data? Check out our EV tool.

> Interested in ensuring the efficient use of EVs. Check out our dedicated editorial sections: Insight & policy | EV news | Charging & infrastructure | Costs & incentives | Benefit-in-kind | EV case studies | EV road tests

Login to comment

Comments

No comments have been made yet.